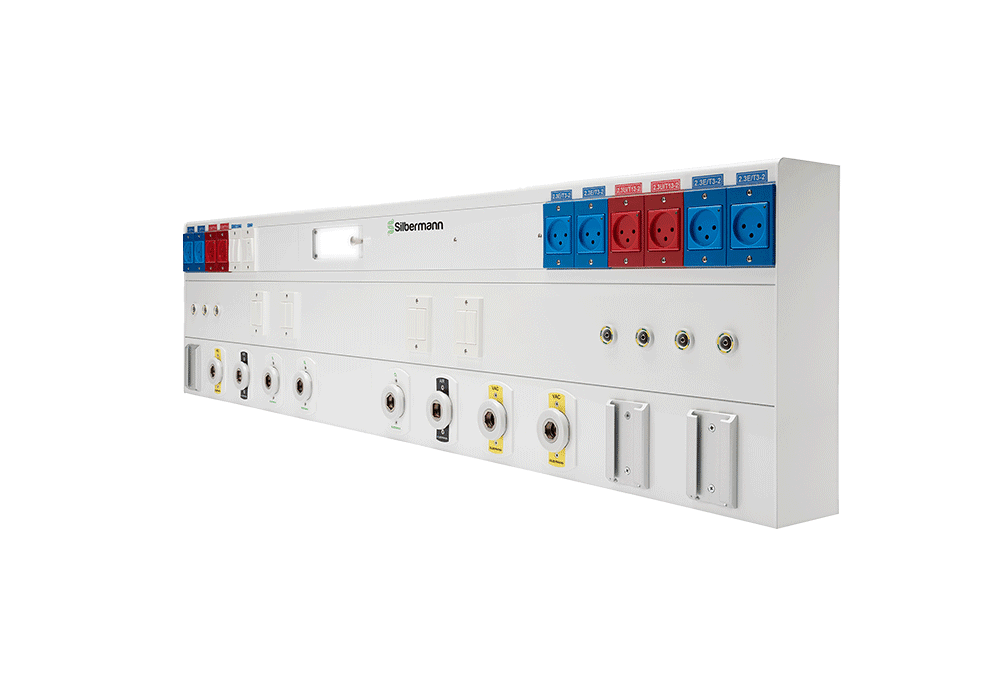

Fully Automatic Digital Medical Gas Manifold (Mazor-XT)

The SILBERMANN Fully Automatic Medical Gas Manifold system is a new approach to medical gas management. It employs advanced electronic system technology that redefines the state-of-art for modern healthcare facilities.

We designed this system to be reliable and to supply continuous gas flow and smooth automatic bank switchover by means of a pneumatic shuttle valve.

The Mazor-XT is designed for backups of the central supply system where high capacities of gas flow is required.

Watch a video about MAZOR XT

Silbermann's Fully Automatic Medical Gas Manifold System for 3 sources

This video introduces the Fully Automatic Medical Gas Manifold System,

equipped with an advanced display touch panel located on the changeover unit door.

The touch panel detects real-time issues to ensure a reliable and secure oxygen supply.

Downloads:

- Continuous supply and smooth

automatic bank switchover, without

pressure fluctuation, using a pneumatic

shuttle valve.

- Maintenance friendly- designed to

enable maintenance during operation

without disrupting the gas supply.

- LCD 12” touch screen display.

- Graphically & digitally display the actual

status of each source- “In use” or “Stand by”.

- Visual & audio alarm signals in case of

low pressure in the main source line,

change between banks, “Below min” and

High/Low line supply pressure.

- Leak detection from manifolds.

- Secured Ethernet-based network

communication between all units.

- Unique secured authentication of each

unit to avoid fake/masking of alarms.

- A color trend arc showing the gas

pressure status on the main line and at each bank

- Optional- display of heaters during idle

and active states.

- Heaters activated during manifold operation.

Automatic adjustment of screen brightness (day & night mode).

- Log History File- Event logging,

recording all alarms and panel activities.

- Periodical maintenance alert.

- Commissioning- Pressure test.

- Customizable text & language.

- Advanced Communication:

- TCP/ IP Modbus

- Remote monitoring through the

building management system available. - Option for remote viewing

through a mobile device or remote

computer.

- Display: 12” HD LCD touchscreen

- Cabinet with door:

- Material - Galvanized steel

- Dimensions – 80x100x25 cm

- Finish – baked on powder coated

- Piping System: All materials are oxygen-

compatible and cleaned for oxygen use.

- Changeover Unit: Pneumatic.

- Flow Capacity: 4 Bar- 90 m3/hr.

- 8 bar- 120 m3/hr.

- Power Supply: 110-220V, 60-50Hz.

- Each cylinder station includes an HP

valve, pigtail with integrated NRV, and

a secure chain.

- An electrical power supply unit

was installed on the external side of the cabinet.

The unit enables the connection

of 2 supplies:- Supply from the mains / essential / UPS

- Supply from batteries (Optional)

- Output connections for area alarms:

Two sets of dry contacts NO/ NC.

- Connection: TCP/ IP Modbus.

- Optional:

- Heaters (for N2O or CO2).

- Bank heavy-duty high-pressure filters.